Advancements in 3D printing technology are progressing at an unprecedented pace, accompanied by a parallel surge in computational power for manipulating and creating intricate geometries. This synergy has the potential to offer architects an unprecedented level of artistic freedom in regards to the complex textures they can generate, thanks to the technology's remarkable high resolution and rapid manufacturing capabilities. If the question of production was out of the way, and architects could now sculpt virtually anything into a facade effectively and efficiently, what would they sculpt?

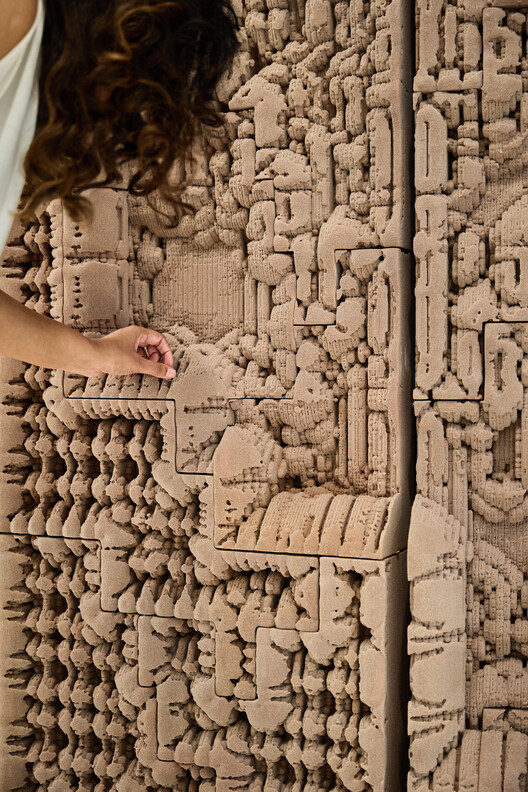

Although we have seen development in the high-resolution 3D printing field in the form of prototypes, in the past year, we have witnessed the materialization of architectural projects using the technology at the facade level. Studio RAP in Amsterdam has effectively manufactured 3D-printed modularized systems that use algorithmically generated geometries. Just last year, they wrapped up "Ceramic House," a boutique store in Amsterdam, constructed by using individually 3D printing ceramic tiles mounted on a laser-cut stainless steel frame, employing algorithmic design inspired by the art of weaving.