Heritage restoration has always been an intricate process that requires delicate balancing between preserving the integrity of historic materials while integrating contemporary techniques that can enhance accuracy, efficiency, and resilience. With the restoration process of Parliament Hill in Ottawa, Canada's capital city, this intersection of tradition and technology is now on full display. The East Block, built in 1865, offers a compelling example of how digital tools can support the efforts of heritage restoration and contribute to a centuries-old craft such as stone carving.

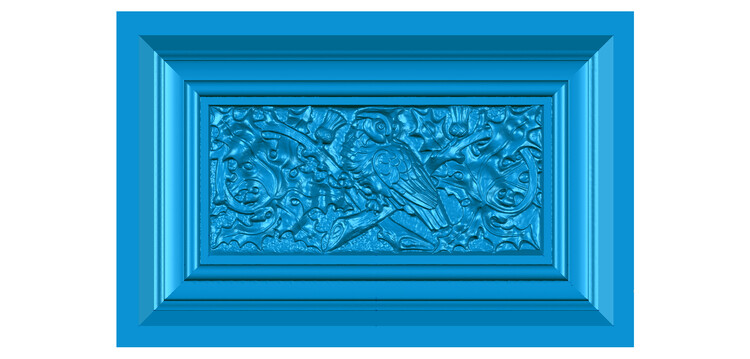

As part of the East Block's conservation work, Public Services and Procurement Canada (PSPC) identified a deteriorating sandstone relief sculpture on the north façade of the East Block, above the courtyard entrance of its 1910 wing. The relief, carved from Berea sandstone, depicts an owl nestled among thistles, measuring 1725 mm by 1120 mm. Unfortunately, the relief was carved with the stone's bedding plane oriented vertically instead of horizontally, which caused the sculpture to deteriorate significantly. The replacement of this sculpture was seen as an opportunity for research. The parliament's dominion sculptor at the time, Phil White, collaborated with the Heritage Conservation Directorate (HCD) and the Carleton Immersive Media Studio (CIMS) at Carleton University in Ottawa, to propose a new workflow for the creation of the replacement relief sculpture. The process undertaken through this joint effort was published in a paper explaining the proposed workflow.

To begin, the team did test runs with different architectural elements to understand different digital acquisition techniques, such as photogrammetry and laser scanning. In the case of the digital fabrication of 3D architectural heritage assets, the ideal 3D models need to have the least amount of noise and the highest possible level of water tightness (a 3D model with no holes). The researchers suggest that, on the one hand, noise can create misleading textures and geometry that do not reflect the original asset. On the other hand, holes in the 3D mesh caused by occlusion (lack of water tightness) or intersecting faces require manual closing in a 3D software, which may lead to inaccurate results.

Related Article

Independent Heritage Documentation: How Digital Tools and Photogrammetry Are Reshaping Preservation Efforts

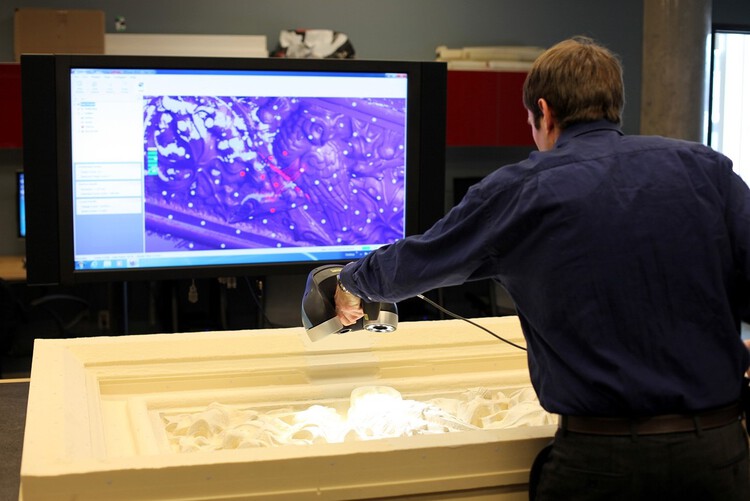

The original 3D model for the bas-relief was taken years prior, using photogrammetry. This digital file was then used to mill a copy of the sculpture in high-density polyurethane foam as a base. The foam replica was then given to the Dominion Sculptor to craft a clay overlay on the areas that had eroded or fallen off, ensuring artistic and historical fidelity. The maquette with repairs was digitized again, this time using a handheld laser scanner. With the new polygon mesh, a new dataset was created and given to a 6-axis robotic arm, which milled the model into a 2200 kg sandstone block within 2 mm of the proposed surface. This was later given to the Dominion sculptor, who would add the final touches, such as surface texture, chisel marks, and subtle expressions, to the sculpture by hand. In this way, they reintroduced the human touch that gives the piece life and authenticity.

Some years later, the parliament's dominion sculptor collaborated again with CIMS and HCD, not to restore but to create carved shields representing all the Canadian provinces for the new Senate Chamber. They did it partly by hand, partly with the aid of robotics, working with high-density polyurethane foam board instead of wood. Mr. White first carved prototypes, which took around six months, which were later digitized by specialists from CIMS. Then they built a photogrammetric 3D model of the carvings. Guided by this digital blueprint, a robotic milling machine roughed out duplicate copies. Mr. White and two assistants then refined details and textures by hand.

This digitally assisted process didn't replace the artisan; rather, it extended their capabilities. It reduced the time and risk associated with handling fragile originals and allowed for a degree of precision and repeatability that would be impossible to achieve through manual methods alone. In effect, it created a layered workflow that bridges the past and present, anchored in craftsmanship, but expanded by computation.

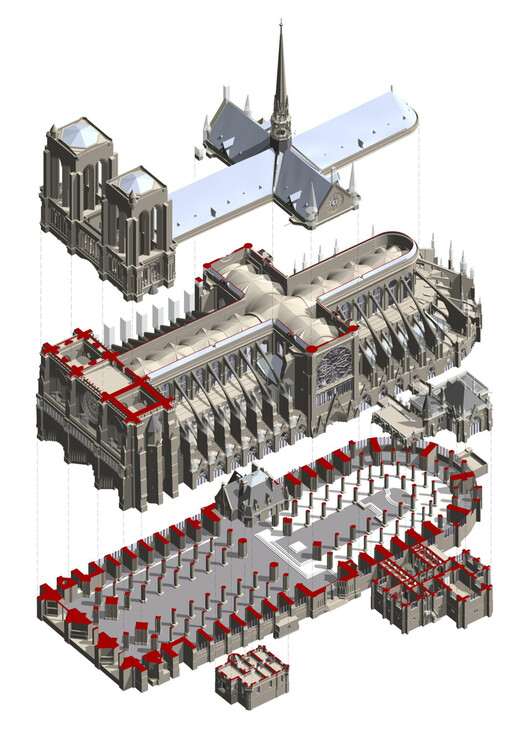

These Canadian examples are not an isolated case. Spain implemented this robot-controlled carving process in 1988 in the construction of the Sagrada Familia in Barcelona. This made the project a pioneer in the use of this technology in architecture. Throughout the years, the cathedral's complexity has required the aid of computers not just to carve stone, but also to calculate its plethora of complex geometries. In France, the restoration of Notre-Dame Cathedral in Paris is perhaps the most globally recognized instance. In the effort to save the monument after the devastating fire of 2019, French architects created a Building Information Model (BIM) to guide the construction, based on lidar scans made in the years prior by art historians. Back in Canada, the Center Block rehabilitation project (the country's largest heritage restoration in its history) is also attempting the integration of BIM into the restoration. This process has enhanced coordination between stone carvers, architects, historians, and engineers, ensuring that the immense complexity of the project is managed systematically.

These examples illustrate the global relevance of technology-assisted restoration techniques such as robot-controlled stone carving. It is possible to highlight a shift from digital as a documentation tool to an active participant in the making process. It is not about replacing the craftsmanship but rather enhancing the ability to respond to modern challenges with both accuracy and artistry. As historic buildings continue to age, and as climate change, urban pressure, and material degradation accelerate the need for intervention, the tools of restoration must evolve. The fusion of scanning, modeling, and robotic carving might not be just a mere technological novelty, but rather it might have the potential to become a cornerstone of 21st-century heritage practice. These methods can ensure that historic materials not only survive but continue to inspire across centuries and continents.

This article is part of the ArchDaily Topics: What Is Future Intelligence?, proudly presented by Gendo, an AI co-pilot for Architects.

Our mission at Gendo is to help architects produce concept images 100X faster by focusing on the core of the design process. We have built a cutting edge AI tool in collaboration with architects from some of the most renowned firms such as Zaha Hadid, KPF and David Chipperfield.

Every month we explore a topic in-depth through articles, interviews, news, and architecture projects. We invite you to learn more about our ArchDaily Topics. And, as always, at ArchDaily we welcome the contributions of our readers; if you want to submit an article or project, contact us.

Editor's note: This article was originally p